SLUP408 February 2022 LM25149-Q1 , LM61460-Q1 , LM61495-Q1 , LMQ61460-Q1

- 1 Introduction

- 2 Defining EMI

- 3 What Causes EMI in a Switched-Mode DC/DC Regulator?

- 4 Existing Passive EMI Filtering Techniques

- 5 Passive Filter Limitations

- 6 AEF

- 7 Spread Spectrum

- 8 DRSS

- 9 True Slew-Rate Control

- 10HotRod? Package Technology

- 11Optimized Package and Pinout

- 12Integrated Capacitors

- 13Conclusions

- 14References

- 15Important Notice

12 Integrated Capacitors

The input current loop is a high di/dt loop that affects EMI at higher frequency ranges. Devices that integrate a high-frequency input decoupling capacitor effectively reduce the high di/dt inductive loop area and help further reduce EMI.

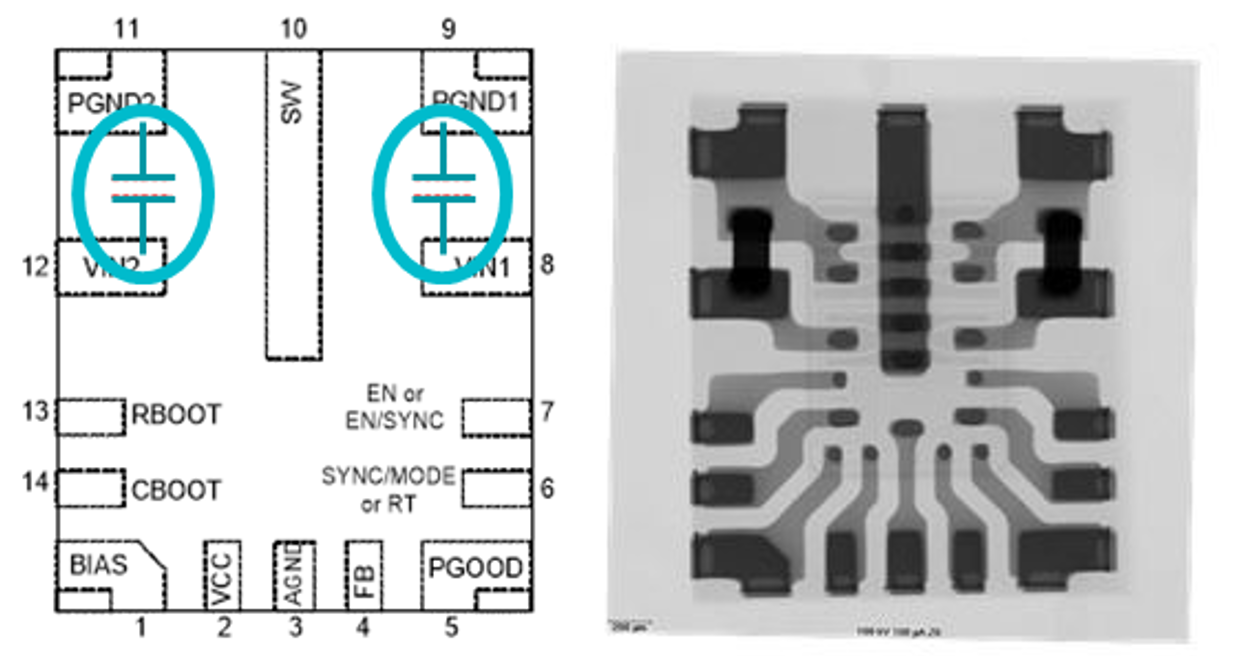

Figure 12-1 provides an example of a device with integrated capacitors. These integrated capacitors are soldered directly onto the internal leadframe of the device, which minimizes the parasitic inductance on the input loop.

Figure 12-1 Integrated capacitors in the

LMQ61460-Q1.

Figure 12-1 Integrated capacitors in the

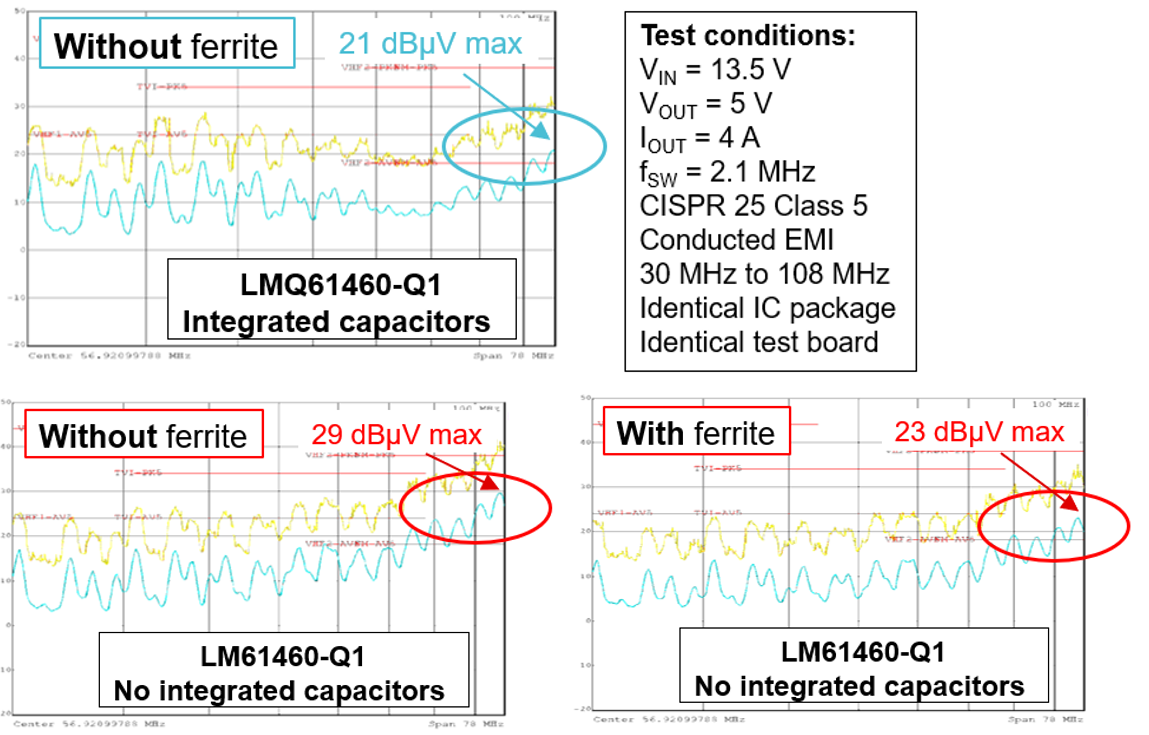

LMQ61460-Q1.The lab EMI measurements shown in Figure 12-2 demonstrate that, without an input ferrite bead, a device with an integrated capacitor provides approximately 8 dBμV of margin compared to a device without an integrated capacitor. When comparing a device with an integrated capacitor to a device without an integrated capacitor – but with an input ferrite bead – the device with the integrated capacitor provides an approximate 2- to 3-dBμV improvement.

Figure 12-2 EMI comparisons between the

LM61460-Q1 and LMQ61460-Q1 automotive buck converters.

Figure 12-2 EMI comparisons between the

LM61460-Q1 and LMQ61460-Q1 automotive buck converters.The LMQ61460-Q1 and LM62440-Q1 step-down converters use this device package construction method. Integrating the input decoupling capacitors inside the device provides a solution that is resistant to EMI and easy to lay out.

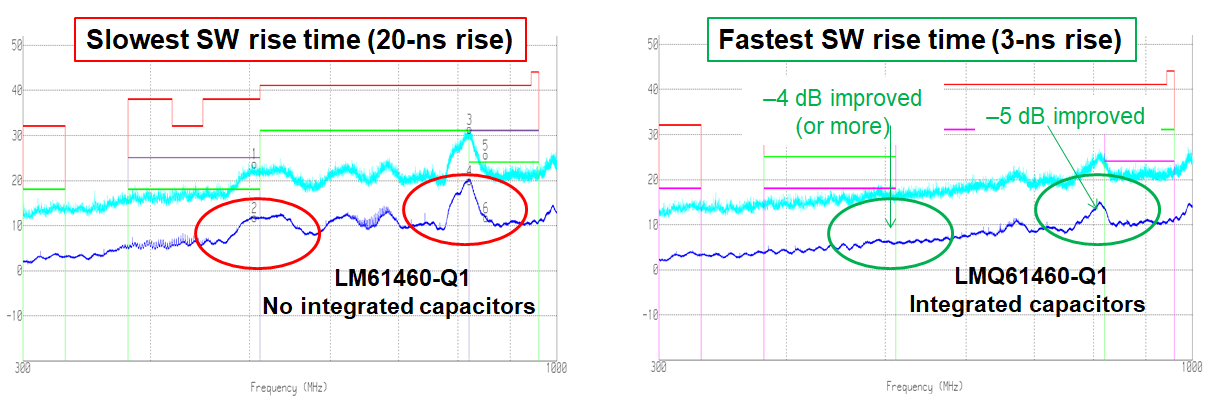

As shown in Figure 12-3, a device with integrated input decoupling capacitors lowers EMI and offers more margin without the need for slew-rate control compared to a device using only slew-rate control and no integrated capacitors. By combining the HotRod package with integrated capacitors, the LMQ61460-Q1 aims to attenuate high-frequency noise at the input path. Any additional device features to help attenuate EMI noise such as true slew-rate control add to a more reliable EMI design.

Figure 12-3 EMI comparisons between the

LM61460-Q1 with slew-rate control and the LMQ61460-Q1.

Figure 12-3 EMI comparisons between the

LM61460-Q1 with slew-rate control and the LMQ61460-Q1.